Electrospinning Accessories

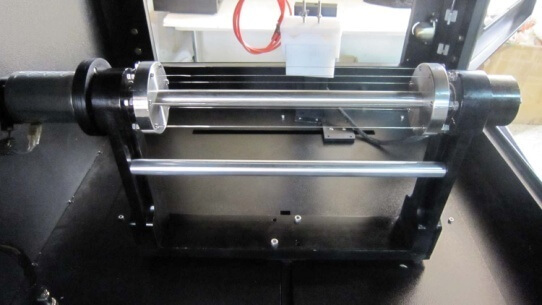

Rotating Drum Collector

In electrospinning, rotating collector is used to produce a uniform nanofibrous

mat. This collection module consists of the rotating drum with a rotation speed

control and display unit. Using this type of collector, randomly oriented nanofibers

are deposited onto the surface of the drum.

Disk Collector

Using this collector, nanofibrous threads or highly aligned nanofibers could be

formed. Furthermore, the effect of linear speed on the fiber formation could be

studied.

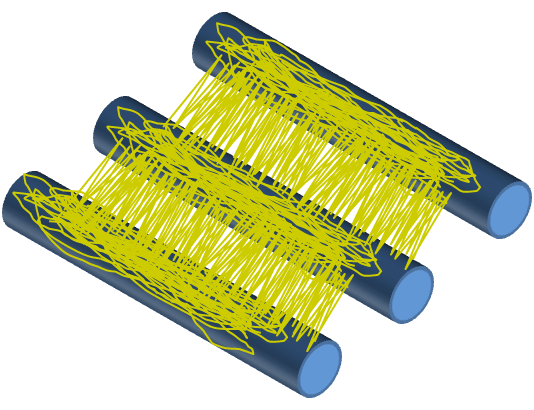

Rotating Wire Collector

The rotating wire collector is used to produce highly aligned nanofibers. It is

composed of thin stainless-steel wires arranged at the same distance from the axis

of the rotation. When the collector is rotating at very low speeds, fibers are also

deposited between the conductive wires. The principle for the formation of aligned

fibers is the same as in the case of the static patterned collector. At higher speeds,

electrostatic and mechanical forces are combined, increasing the degree of alignment

of the individual fibers. To achieve very good fiber alignment, the collector speeds

could be much lower than those of the rotating drum collector.

Mandrel Collectors

Mandrel collector is a device to make tubular nanofibrous samples. The mandrel collector

contains a stage, controller and a set of interchangeable mandrel collectors. The

rotating mandrel collector could be used either as a stand-alone collector or could

be integrated into lab-scale electrospinning machine. Six mandrels with the diameters

of 1, 2, 3, 4, 6 and 8 mm are included in this product.

Wet Collector

Wet collector is designed for electrospinning of polymers which could not be dissolved

in normal solvents. A typical example of these types of collectors is cellulose.

Common solvent for cellulose is liquid crystals which do not evaporate during jet

traveling. So instead of evaporation, coagulation mechanism is used to produce nanofibers

from the electrospinning jet. For this purpose, a solution bath is used with the

rotating drum to solidify the jet and get the final fibers.