Industrial Nanofiber Production Line (INFL6100B)

FNM Industrial Nanofiber Production Line (INFL) is an industrial-scale machine designed to produce polymeric and ceramic nanofibers for a variety of applications. It can accommodate 1 to 6 electrospinning units based on the customer requirements. The INFL allows for precise control of electrospinning parameters, including spinneret and collector settings, working distance, substrate linear movement speed, working temperature, and operation time, all managed through an integrated advanced control system. The machine offers excellent user safety in handling high-voltage power supplies and chemical solvents.

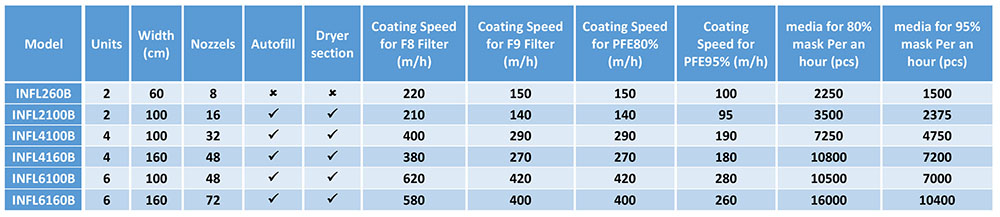

Using this production line, nanofibers can be deposited onto various substrates at an industrial scale, making it particularly effective for producing nano-filters and nano-respiratory facemasks. The nanofiber coating rate ranges from approximately 50 to 800 meters per hour depending on the number of electrospinning units utilized.

FNM INFL nomenclature:

INFLXYYYZ

X: Number of electrospinning units (1, 2, 4 or 6)

YYY: Maximum electrospinning width (60, 100 or 160 cm)

Z: (B) Blown System; (C) Cartridge System

INFL260C: Industrial Nanofiber Production Line, 2 units, Max width: 60 cm, Cartridge System

INFL4100B: Industrial Nanofiber Production Line, 4 units, Max width: 100 cm, Blown System

INFL6160B: Industrial Nanofiber Production Line, 6 units, Max width: 160 cm, Blown System

Description

Flexibility

• A wide range of polymers and composites can be electrospun.

• Higher output compared to conventional needle and needleless electrospinning machines.

• Various product specifications, including porosity, morphology, diameter, and bead loading capacity, can be achieved.

• The process is straightforward and cost-effective.

• Different types of polymers, including synthetic, biodegradable, and natural polymers, as well as polymer/composite blends, can be processed.

Easy Operations and Convenient Functions:

• Electrospinning parameters can be fully controlled through a user-friendly HMI panel.

Nanofiber Diameters:

• 60 to 500 nm

Systems, Control Systems, and Panels:

• PLC system for controlling operating conditions

• Two 10” Human Machine Interfaces (HMI)

• Independent control of electrospinning parameters for each spinning unit

• Utilization of both positive and negative high voltage power supplies to achieve optimal electrospinning condition

• Blown System:

o Controls air pressure

• Scan System:

o Controls scan speed

o Controls the start and end position of the spinnerets

• Displays humidity in the chambers

• Advanced digital high-voltage control systems

• Emergency stop button for safety

Input Power:

• 380 volts, three phases, 50-60 Hz

• Single Phase: Optional

Power Consumption:

• Heater System: Maximum 2.25 kW

• Dryer: Maximum 2.25 kW

• Control and High Voltage: Maximum 3 kW

High Voltage:

• 0-35 kV DC, positive polarity, precisely adjustable

• 0-35 kV DC, negative polarity, precisely adjustable

• Digital voltage monitoring (accuracy: 0.1 kV)

• Independent control for each unit

• Control by HMI

• HV’s current limit to minimize the risks

Collector:

• Stainless steel plate for static fibers collection or rotating drum for coating desired substrates

• Working distance: (C): 7-17 cm; (B): 20-30 cm

• Rotating speed: 0-50RPM (synchronized with substrate)

• Diameter: 17 cm

Heating System:

• From room temperature up to 45 °C

Ventilation:

• Solvent removal from the chamber using a ventilation fan with a programmable operation time

Dryer System:

• Substrate dryer chamber with temperature control

Substrate Winder:

• The servo motor control system

• Substrate speed: 1 to 50 or 50 to 800 m/h

• Maximum substrate width options: 60, 100, or 160 cm

• Edge control system

• Tension control system

• Substrate cutting section (Optional)

Case:

• 6 doors for easy access to all parts of the system

Weight:

• Varies by model and (from about 1500 for INFL260 to about 4000 kg for INFL6100)

Dimension:

Varies by model:

• Length: 370 - 800 cm

• Height: 220 - 260 cm

• Width: 210 - 250 cm